Advanced 3D Modeling of Pistons and Rings Using FEV Tools.

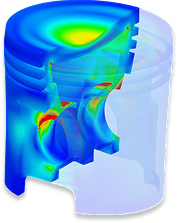

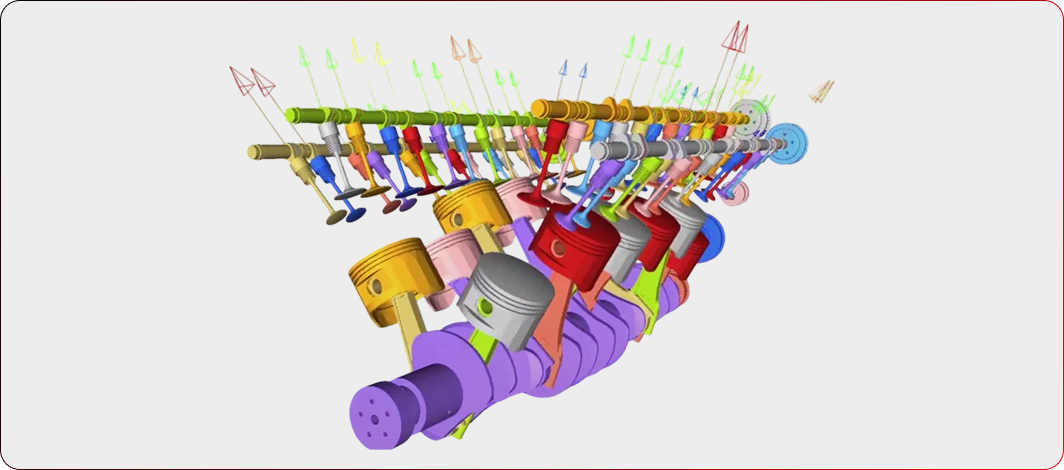

Eurodizel became the first company in India to implement a 3D system for piston and ring dynamics analysis, surpassing competitors.

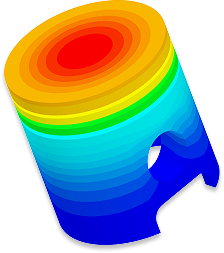

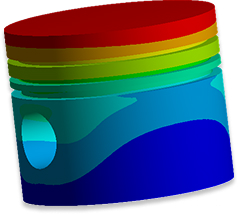

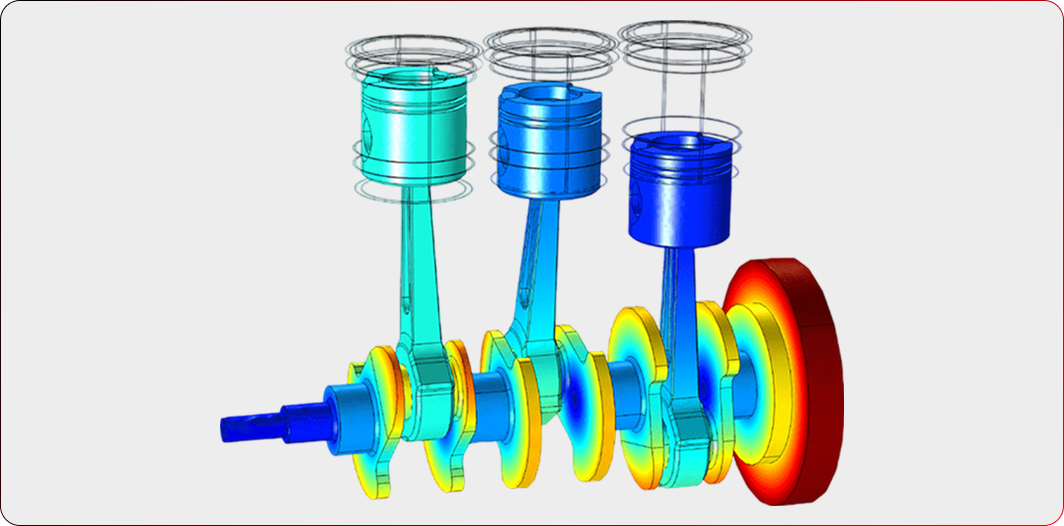

The integration of secondary piston motion modeling and ring dynamics enables accurate prediction of gas blow-by, gas flow, and friction.

The analysis includes the evaluation of comprehensive wall pressure and the resulting forces affecting ring operation modes.

3D simulation of secondary piston motion dynamics helps reduce noise, vibrations, and irregularities.

Diamond-Like Carbon (DLC) – Offers exceptional hardness, low friction, and high wear resistance.

PVD & GN Coatings – Advanced physical vapor deposition (PVD) and gas nitriding (GN) for enhanced durability.

Nano Diamond Coated (NDC) (Patent Applied) – Cutting-edge nano-coating for superior performance and longevity.

Moly Chrome Ceramic (MCC) (Patented) – A proprietary blend ensuring optimal wear resistance and reduced friction.

Chrome Moly Coated – A tough and resilient coating that balances durability and smooth operation.

Moly Sprayed – Provides excellent lubrication and thermal stability under extreme conditions.

Fe-safe – Fatigue Life Prediction for enhanced durability and reliability.

Tosca Topology Shape Optimization to achieve extreme weight reduction in piston assemblies.

Fe-safe – Fatigue Life Prediction for enhanced durability and reliability.

IP Low Friction HCV Pistons – Designed to minimize friction and improve fuel efficiency.

DLC Pin & Rings – Diamond-like carbon coatings for superior wear resistance and reduced friction.

IP Glide – Special Oil Control Ring Profile – Optimized for low friction and improved oil management, meeting BSIV & BSVI standards.